Loading Dock Levelers

Dock levelers bridge the gap and height difference between the dock and the trailer. They also compensate for the up and down float of the trailer bed during loading. A dock leveler includes a ramp (hinged along its rear edge) and a lip (hinged at the front of the ramp). When not in use, the dock leveler is stored in its neutral position, flush with the loading platform floor. To use a dock leveler, the operator raises the ramp and the lip swings out. With the lip extended, the operator lowers the ramp until the lip rests on the truck.

Let’s Get Started

"*" indicates required fields

DLM Dock Leveler Manufacturing

DLM Dock Leveler Manufacturing has been manufacturing loading dock levelers in the USA since 1961. These premium levelers have been known as the strongest and most durable dock levelers in the industry providing a smooth and efficient loading process. DLM dock levelers can be activated automatically or mechanically and are available as pit-style, edge-of-dock or vertical storing. Each leveler type comes in a variety of sizes and capacities to meet any loading dock requirements.

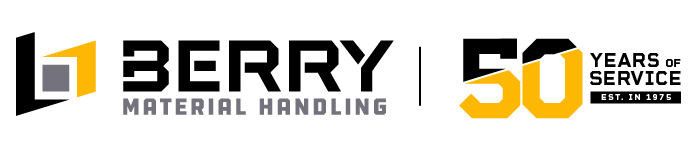

HYDRAULIC DOCK LEVELERS

Hydraulic dock levelers are push-button activated and have the highest capacity available.They utilize fully powered raise and lip extension functions with hydraulic cylinders and individual or multi-unit hydraulic pump and motor stations.

Features

- Push-button activation

- Hydraulic operation

- 25,000 – 60,000 CIR

- Structural steel w/ plate outboards, four-sided box construction

- Piano style front and rear hinges

- Inverted hoist cylinder with external velocity safety stop

- Standard Lip Cylinder

- Sliding toe guards

- Sequence valve

- Max Standard Width – 7′

- Max Standard Length – 10′

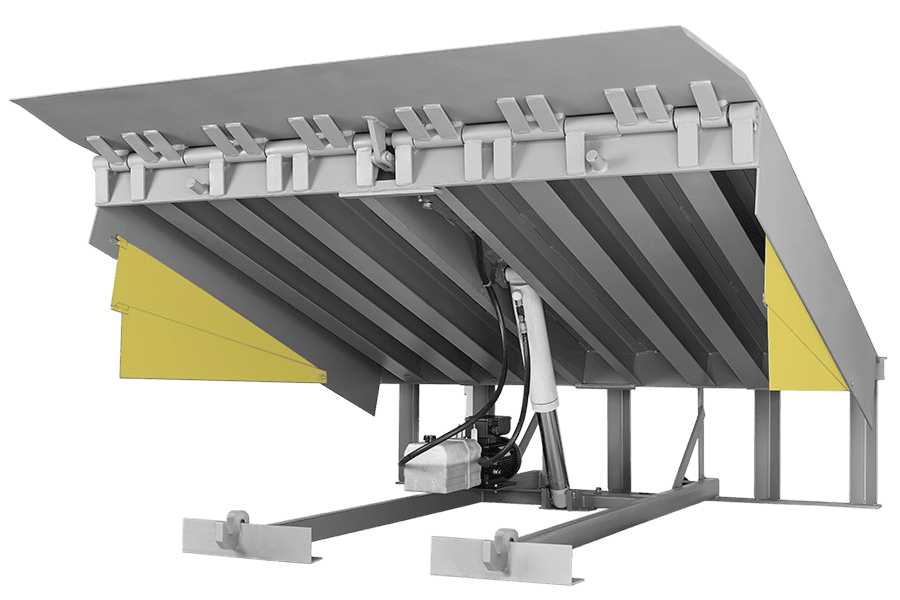

AIR POWERED DOCK LEVELERS

Air-powered dock levelers are an economical alternative to hydraulic levelers, but are still operated with a push-button activation. The use of an air bag or bellows system is used to raise and lower the deck.

Features

- Push-button activation

- Air powered

- 30,000 – 50,000 CIR

- Structural steel w/ plate outboards, four-sided box construction

- Piano style front and rear hinges

- Low-pressure high-volume air bag with blower motor

- Mechanical Lip Operation

- Sliding toe guards

- 115V Single phase electric blower motor

- Optional Barrier Lip

- Max Standard Width – 7′

- Max Standard Width – 10′

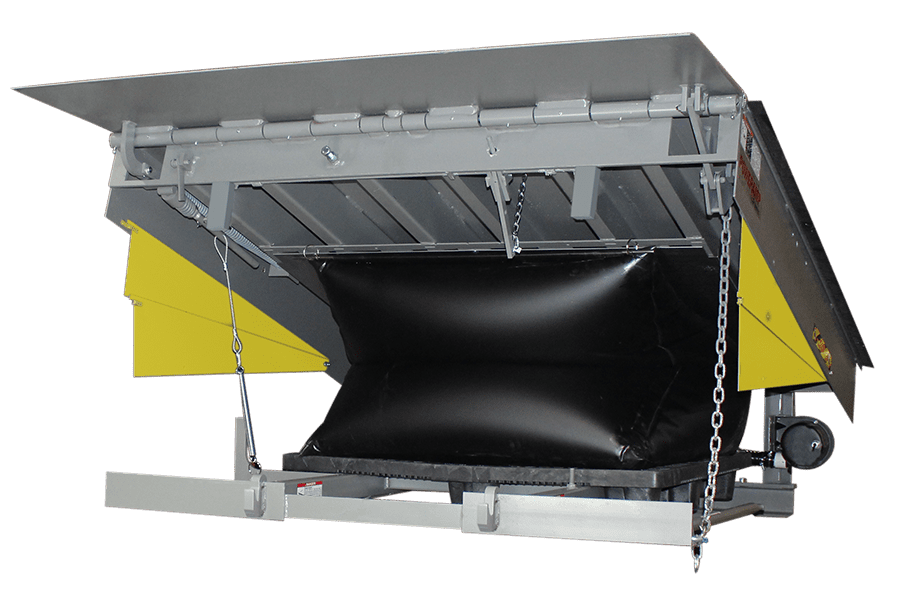

MECHANICAL DOCK LEVELERS

Mechanical levelers use a pull chain activation to raise the deck. The operator simply walks the deck back down to the bed of a trailer or to a stored position. These levelers are equipped for extreme float conditions.

Features

- Manual Activation

- Mechanical operation

- 30,000 – 50,000 CIR

- Structural steel and four-sided box construction

- Piano style front and rear hinges

- Multi-spring centerally located off pit floor

- Mechanical Lip Operation

- Optional sliding toe guards

- Cam control counter balance

- Max Standard Width – 7′

- Max Standard Length – 10′

EDGE-OF-DOCK LEVELERS

DLM Edge-of-Dock Levelers mount directly to the dock face and provide a recommended working range of +/-3″ and a maximum operating range of +/-5″ above or below dock. The units are offered with either mechanical or hydraulic operation.

Mechanically-operated edge-of-dock levelers are the largest selling edge-of-dock levelers in the industry. DLM’s dual extension spring lift mechanism offers proven efficiency and durability. Careful engineering and rugged construction ensure extended life. Operation is safe and easy.

Need Installation & Maintenance Services?

Berry Material Handling offers installation for all major material handling products as well as custom fabrication for your special projects. We can also tailor preventative maintenance and service programs to identify problems before they arise, helping to reduce costly breakdowns and downtime. We customize the maintenance to fit your needs and provide services including equipment review, lubrication, tightening and adjustments.