- Equipment

- Rental

- Parts & Service

- Training

- Warehouse

- Fabrication

- Industries

- Contact

- Blog

- Payment Portal

- Apply for Credit

- Subscribe

Vehicle Restraints

Increase safety at the loading dock. Many forklift accidents occur every year that are caused by a truck prematurely departing from the dock or creeping away due to loading and unloading momentum. Installing a Vehicle Restraint from DLM can help prevent these accidents by securing a trailer to the dock and providing better communication between the truck driver and dock attendant.

Let’s Get Started

"*" indicates required fields

Models

TPR® Series Automatic Restraint

The DLM® TPR® truck positioned vehicle restraint is designed to automatically position itself and secure a trailer’s rear impact guard (RIG) to reduce the likelihood of premature trailer separation during the loading/ unloading process.

Features

- LOW PROFILE DESIGN

- ZINC PLATED FINISH

- EXCLUSIVE GEAR MOTOR

- NHTSA

- ADVANCED COMMUNICATION

- SIGNS INCLUDED

PowerStop® Series Automatic Restraint

The PowerStop® fully automatic vehicle restraint (AAL) is an easy-to-install, affordable restraining system. It comes equiped with a RIG sensor bar that notifies dock workers if the restraint’s arm is not securely engaged with the trailer’s Rear Impact Guard.

Features

- AUTOMATIC LIGHT SEQUENCING

- REMOTE POWERPACK

- EQUIPMENT INTERLOCKING OPTION

- RIG SENSOR BAR

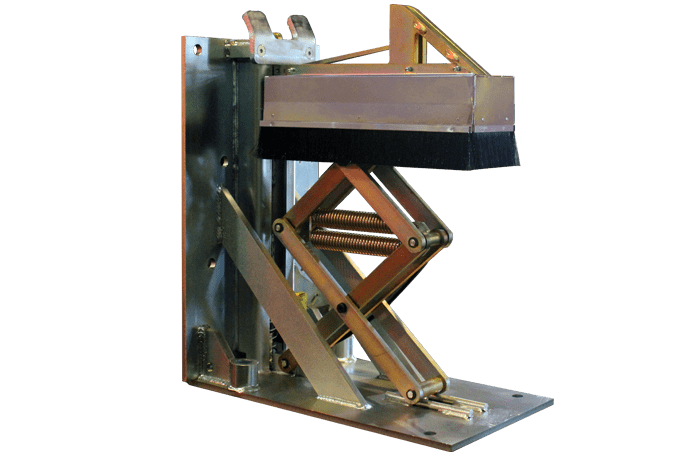

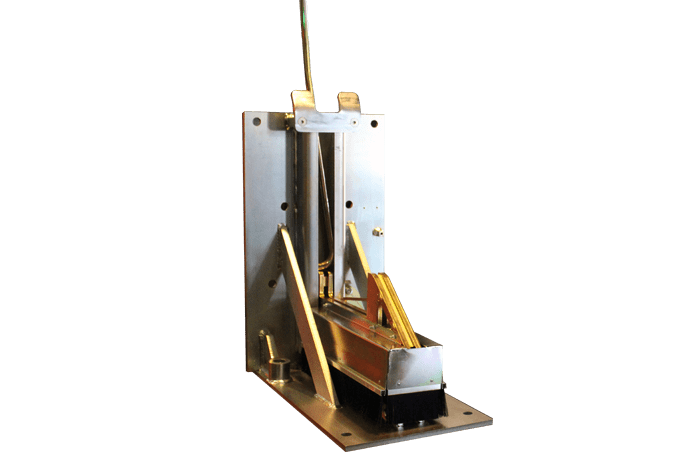

PowerStop® Series Manual Restraint

The PowerStop® is a non-impact, self-aligning, mechanically operated truck restraining system. An optional light communication package can be added to the MML and MAL, which can also be upgraded to iDock Controls with an interactive message display.

Features

- EQUIPMENT INTERLOCKING OPTION

- RIG SENSOR

- OPTIONAL AUTOMATIC OR MANUAL LIGHT SEQUENCING

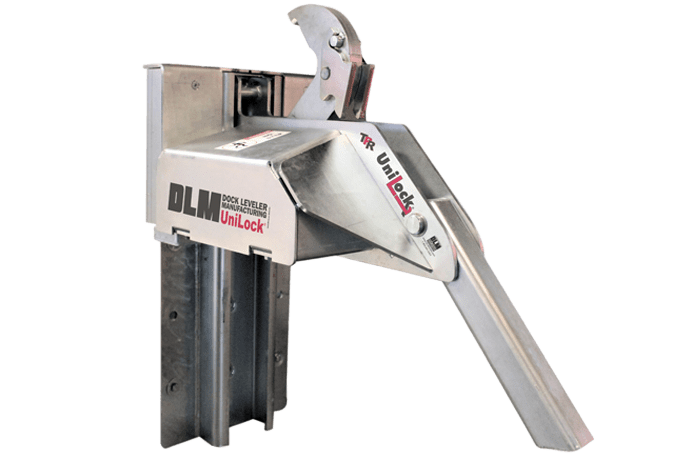

TPR UniLock® Automatic Restraint

The TPR UniLock® is the only trailer-postioned vehicle restraint that can automatically remove “RIG Wedge” pressure. RIG Wedge is caused when the trailer is pushed forward during loading/unloading and the trailer’s Rear Impact Guard (RIG) applies so much pressure to the restraint’s hook that the truck driver must reverse the trailer in order to release the restraint.

Features

- ADVANCED CAM DESIGN

- UNIVERSALLY EFFECTIVE

- EXCLUSIVE GEAR MOTOR

- LOCKING MECHANISM

- ADVANCED COMMUNICATION

- SIGNS INCLUDED

UniChock Vehicle Restraint

The UniChock is a wheel-based trailer restraint with advanced light communication and available as a standalone unit or integrated with other dock equipment. Universally effective in most conditions, the unit helps prevent unexpected trailer departure or movement from the loading dock during the loading process.

Features

- UNIVERSALLY EFFECTIVE

- AUDIBLE ALARMS

- LIGHTWEIGHT, DURABLE DESIGN

- ADVANCED COMMUNICATION

- REPLACEABLE TRACTION TEETH

Need Installation & Maintenance Services?

Berry Material Handling offers installation for all major material handling products as well as custom fabrication for your special projects. We can also tailor preventative maintenance and service programs to identify problems before they arise, helping to reduce costly breakdowns and downtime. We customize the maintenance to fit your needs and provide services including equipment review, lubrication, tightening and adjustments.